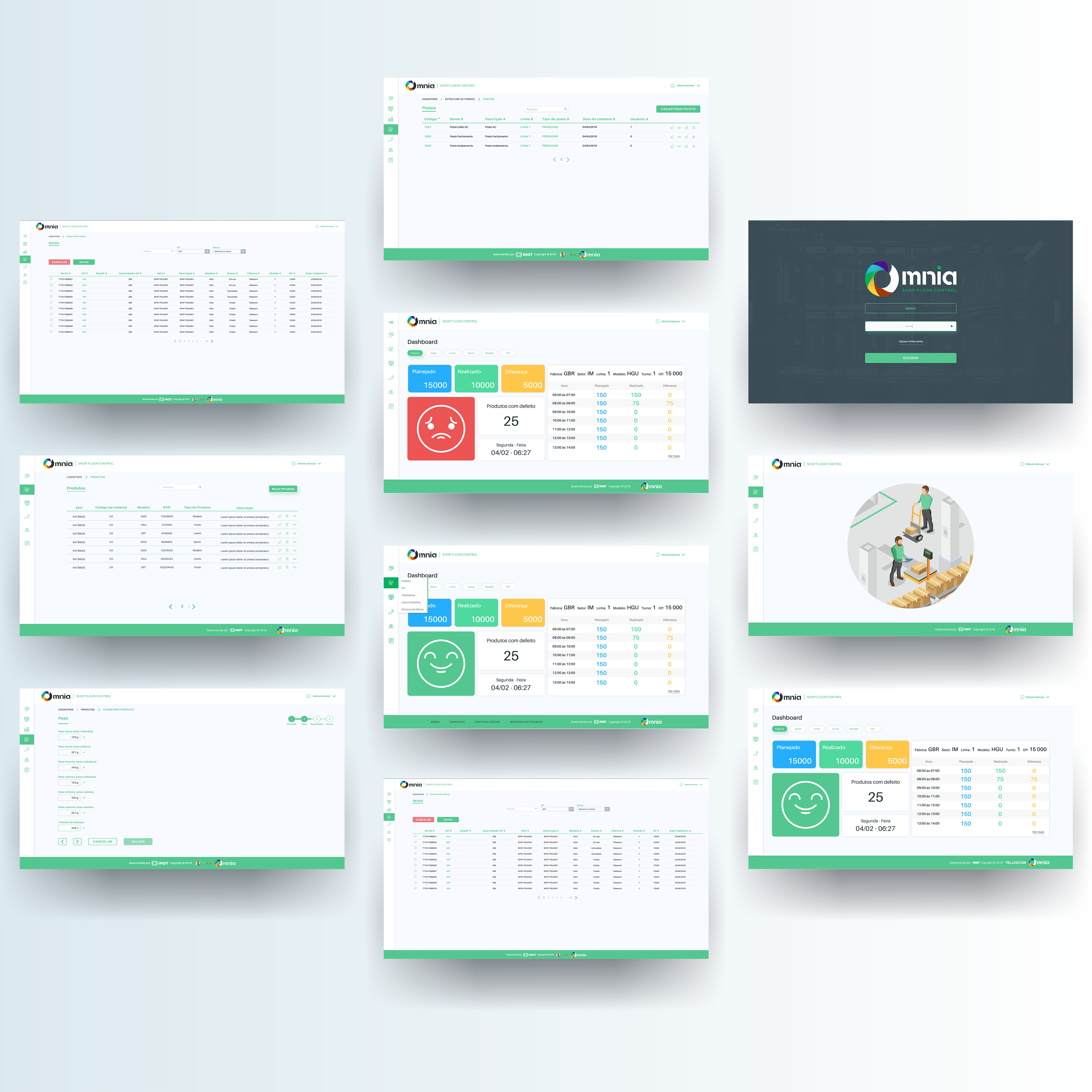

Omnia is a comprehensive factory control and monitoring system designed to unify six previously separate systems into a single, integrated platform. Spanning the entire production lifecycle, from initial manufacturing to distribution tracking, Omnia streamlines factory operations, enhancing efficiency and real-time monitoring. Developed in close collaboration with TELLESCOM, a leading producer of modern telecommunications equipment, the project aimed to revolutionize the way factory processes are managed, without disrupting ongoing production. Through user-centered design and Lean Inception workshops, we ensured a seamless transition that met both business and technical needs.

Omnia is an integrated factory control and monitoring system, which operates from the beginning of the production process to distribution tracking.

TELLESCOM produces the most modern and complete modems, routers, setup-boxes, adapters, WI-FI signal repeaters, IOT services and production, licensing and distribution of digital content. The factory runs using 6 different systems.

Create a system that unifies 6 different systems into 1

We needed to study and decide which method we are going to use and of course adapt. The best option was Lean Inception, a collaborative workshop to align a group of people on the minimum viable product to be built. Created by Paulo Caroli, its main objective was to reduce the time of "traditional" Inceptions, which took two to four weeks to complete with a plan almost always complete with the release of a product, for only one week. There were 5 days of intense immersion with the client in a War Room, where we did the workshop of Product Vision, The product Is, Is Not - Does, Does Not, Personas, Features Brainstorm, Technical, Business and UX Review, Users' Journey, Sequencer, Effort, Time and Cost and finally theCanvas MVP.

But we also need to talk to real users. Then a series of interviews were conducted in several production lines of the factory, to identify problems and opportunities, and understand the factory work flow. And in the end we gathered all the knowledge in a design studio, is a collaborative and creative method to solve problems where Designers, Developers, Product Managers, Quality Assurance and Stakeholders co-create and explore alternatives through design.

The design studio is a way to generate and evaluate many ideas of a problem quickly, through sketching, iterating and critiquing.

The implementation of Omnia was a long and demanding project, taking over a year to complete. However, with a gradual rollout, the transition to the new system was seamless and well-received by users. The system was integrated into all aspects of the factory operations without the need to interrupt the production process. This ensured a smooth and uninterrupted transition from the old systems to Omnia.